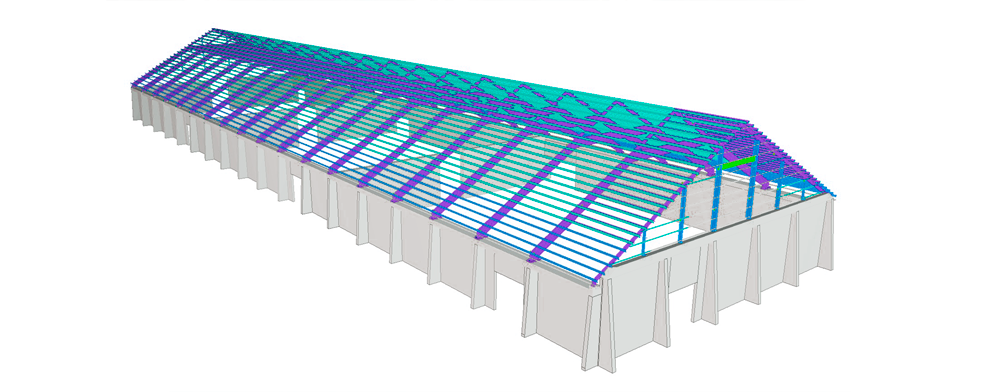

En el puerto exterior de La Coruña, hemos construido una nave industrial utilizando perfiles armados de canto variable en calidad S275JR, con un acabado superficial galvanizado para mayor durabilidad. La estructura destaca por su impresionante diseño, con una luz sin apoyos intermedios de 50 metros y una altura a cumbrera de 27 metros, ofreciendo un amplio y funcional espacio. Este proyecto combina precisión, resistencia y eficiencia para satisfacer las exigencias del entorno industrial.

Nave industrial

consignario portuario

Edificación industrial

Edificación industrial

Nave industrial fabricada a partir perfiles armados de canto variable en calidad S275JR, con un acabado superficial galvanizado situada en el puerto exterior de La Coruña, esta nave tiene una luz sin apoyos intermedios de 50 metros y una altura a cumbrera de 27 metros.

Especificaciones

Especificaciones

Capacidades y especificaciones técnicas de este proyecto:

Ubicación

Ubicación

A Coruña, España

Duración

Duración

12 semanas